Carbitool extends its tool coating and regrinding services

27.08.2019

Acquisition of Carbitool by Sutton Tools, another Australian family manufacturing business, has seen a number of changes – but the woodworking tool specialist continues to manufacture at its factory in Victoria and is expanding its range.

Continuity at its Moorabbin premises ensures both the continued engagement of its highly qualified, long-standing production personnel and the ongoing development of specialised tooling and manufacturing processes. Carbitool has made other improvements in recent months, particularly in its warehousing operations and on the workshop floor.

Responding to changing needs

The ongoing expansion of its router bit range ensures Carbitool can continue to meet the growing requirements of a demanding market – as well as a new and developing market, as new materials continue to become available to the building and manufacturing industries.

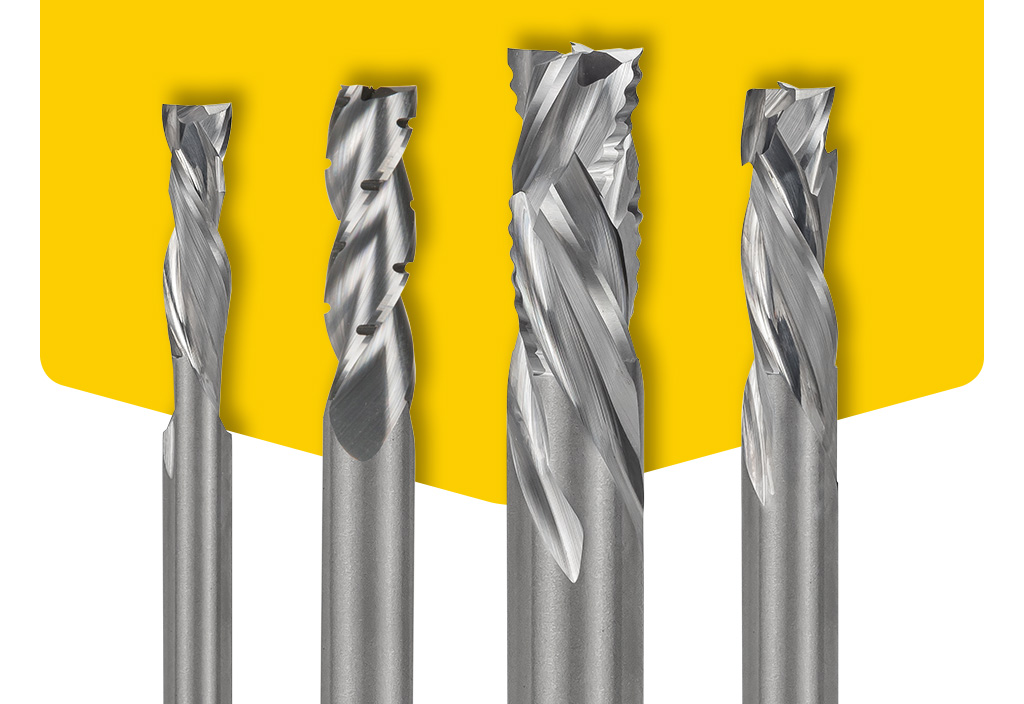

The expansive Carbitool solid carbide spiral flute range of cutters caters in part for composite material variations and newly formatted board product as it enters the supply chain.

Where only recently a workshop may have only machined timber product or aluminium, it may now face the challenge of machining Aluminium Composite Panel (ACP), composite panel with steel/stainless steel, fibre cement sheet, carbon fibre, fibre-reinforced plastic or fibreglass. Some may be machining plastics – from hard to soft, Bakelite to Nylon (PA) – including PET, PE, PVC, PP, PLA, PC, Acrylic (PMMA), Acetal (POM), ABS and even Polystyrene (PS).

The Carbitool full range for dealing with this extensive range of materials has been illustrated in a new and improved catalogue, download your copy today.

Compressor Cutter Range

Carbitool’s range of compression cutters continues to grow – now encompassing single-flute, 2-flute, 3-flute, 4-flute and 4-flute rougher/finishers. All of the series, except the single flute, are available in short upcut for morticing as well as long upcut versions.

Using coatings on compression cutters enhances their suitability and performance for a wide range of applications.

Benefits of advanced coatings

Suitability of cutting tools to perform adequately on difficult materials is now enhanced by the application of advanced coatings such as Titanium Nitride (TiN), Titanium Carbon Nitride (TiCN) and Titanium Aluminium Nitride (TiAIN). With more difficult to machine materials entering the market regularly, solid carbide tools are increasingly coated with these and other advanced coatings such as Chromium Nitride (CrN) and Aluminium Chromium Nitride (AlCrN).

All coatings offer longer tool life and the ability to obtain superior finishes. Carbitool also holds stock of solid carbide spiral flute tools in a range of coatings. In addition, access to Sutton Tools’ coating facility, Surface Technology Coatings, now allows rapid turnaround on tool coating services for special requirements.

Extended regrinding capabilities

Carbitool has also recently added two Australian-made ANCA RGX Automatic CNC machining centres from the Sutton Tools regrind centre. This improves its in-house capabilities for sharpening the complete solid carbide spiral flute range, including compression cutters. The result is even greater accuracy and faster turnaround.

For more information on Carbitool products and regrinding services download the new catalogue, or contact us.